Quality Gearbox Repair: Enhancing Performance with Expertise

Ensure Your Gearbox Operates Smoothly with Apex’s Dedicated Repair Services.

Decades of Gearbox Repair Expertise at Apex

With a rich history spanning 70 years and 35 years of expertise in gearbox repairs, Apex Industrial Automation is your trusted partner for keeping your equipment in top condition. Our dedicated team is available 24/7 to ensure minimal downtime and maximum efficiency.

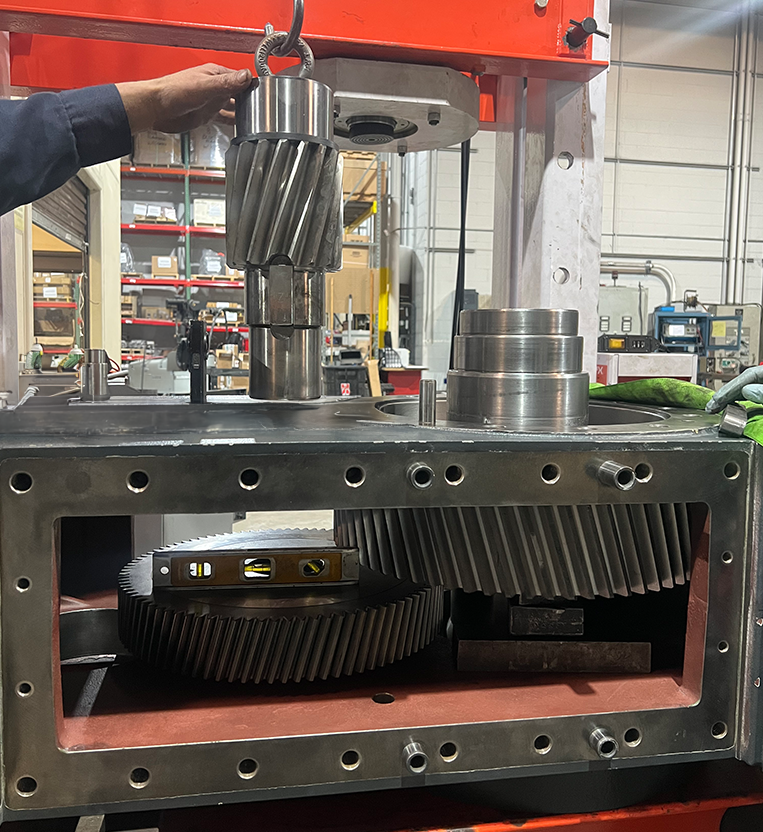

Our skilled technicians have the knowledge and experience to repair and rebuild various gearbox types, including Helical, Spur, Worm, Planetary, Spiral Bevel, Hypoid, and Traction Drives. Equipped with advanced tools and technology, we’re committed to diagnosing and resolving issues swiftly, guaranteeing your gearboxes’ reliability and performance. Trust Apex for all your gearbox repair needs and experience the difference our expertise and dedication can make.

Need Assistance?

Why Choose Apex for Gearbox Repair?

Apex Industrial Automation understands the essential role gearboxes play in the smooth operation of your machinery. Our dedication to providing top-notch service and results sets us apart and makes us the go-to choice for gearbox repair.

Our commitment to excellence and a focus on customer needs are just a few reasons why partnering with Apex for gearbox repair is a wise decision for your business.

Discover how our unique advantages ensure your gearboxes function optimally.

EASA Accredited

Apex follows the latest Electrical Apparatus Service Association (EASA) repair guidelines, AR100-2020, and as one of only eight EASA shops in Illinois, we repair to the highest standards and best practices in gearbox repair.

ANSI Repairs

Apex adheres to the American National Standards Institute (ANSI) guidelines for all repairs. This helps ensure that every gearbox we service meets this esteemed organization’s rigorous quality and safety standards.

Distributor Advantage

Many of our competitors need to buy their components from distributors like us, incurring additional expenses. This advantage enables us to acquire replacement and repair parts at a lower cost, offering an economical solution for our customers.

24/7 Emergency Support

Our emergency repair service is available 24/7, even on holidays. We help you reduce downtime and keep your operations running smoothly when you need it most.

Full-Service Repair Shop

As a leader in gearbox and related equipment repair, our comprehensive repair and machine shop is equipped to handle all your needs with precision.

Local Presence

Our strategically located repair shop in Northern Illinois ensures swift and efficient service to maintain uninterrupted operations.

Affordable Repair Solutions

We understand the importance of minimizing downtime and reducing costs. We offer competitive pricing for our gearbox repair services, ensuring you receive cost-effective and efficient solutions.

Customer-Centric Repairs

At Apex, we prioritize every customer, ensuring you receive the attention and customized solutions you deserve. Our customer-centric approach ensures your complete satisfaction with our gearbox repair services.

Quick Gearmotor Repairs

We keep Nord & SEW stators in-house for rapid gearmotor repairs. Our inventory of stators allows us to quickly address a wide range of gearmotor issues, providing you with efficient and reliable repair solutions.

One-Year Warranty on Gearbox Components

We provide a one-year warranty on parts for gearbox repairs, ensuring your confidence in the quality of our industrial components.

Experienced Gearbox Specialists

Our team of expert technicians at Apex Industrial Automation is dedicated to your success. With a commitment to personalized service, we tailor our gearbox repair solutions to meet your specific needs and requirements.

Precision In-House Machining

Our in-house machining capabilities allow us to create new parts with precision, ensuring quick turnaround times and accurate repairs for your gearboxes—Trust Apex for reliable and precise gearbox repair services.

Apex Industrial Automation is committed to offering outstanding gearbox repair services that extend beyond simple fixes. Our goal is to enhance the overall performance and longevity of your gearboxes. You’re partnering with a team dedicated to providing top-tier service and results by choosing Apex for your gearbox repair requirements.

Rely on Apex to guarantee that your operations function with unparalleled precision and efficiency.

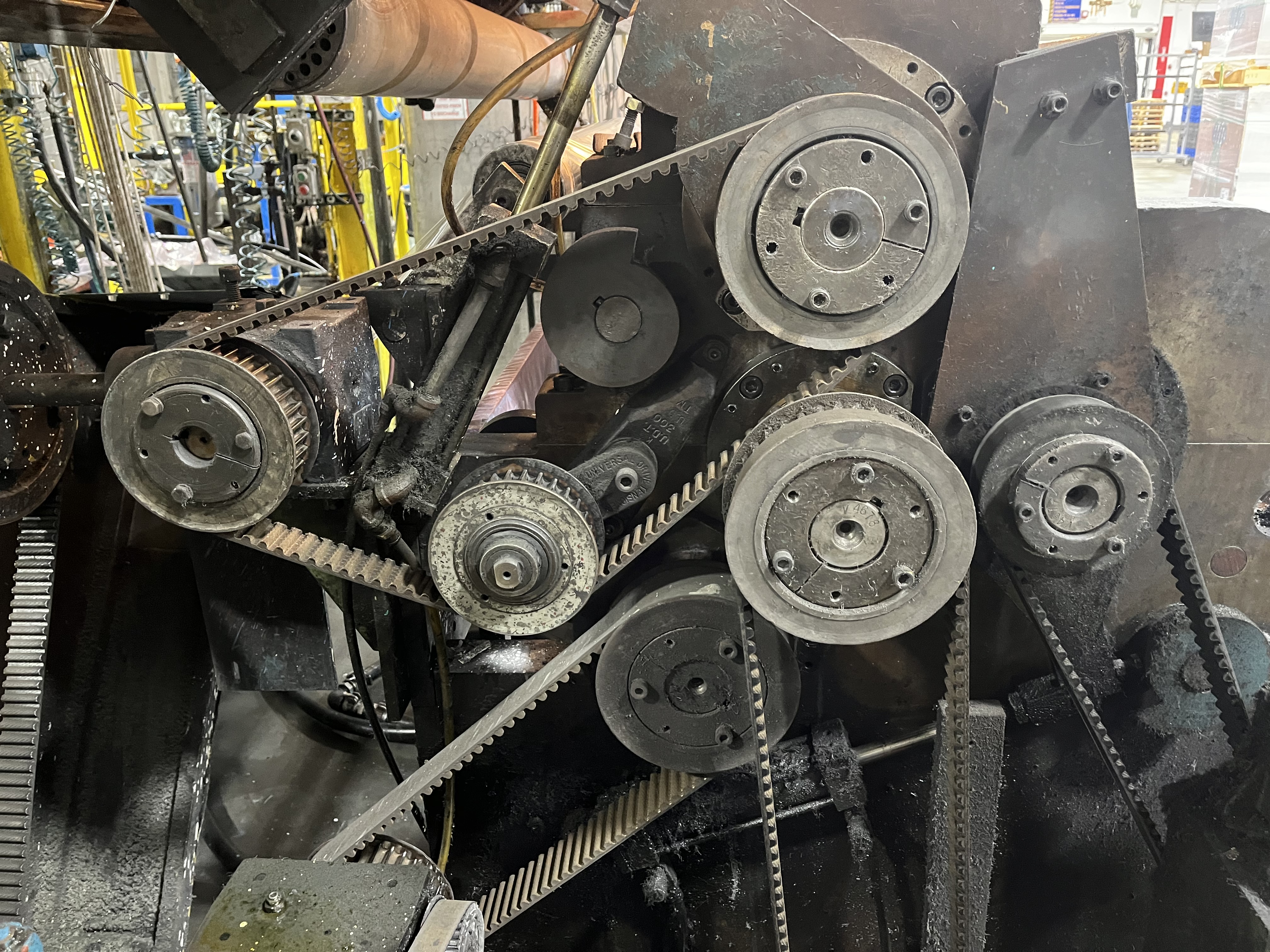

Gearbox Makeovers: Before and After

Before

Legacy Link-Belt PIV mechanical variable speed drive units on the production line.

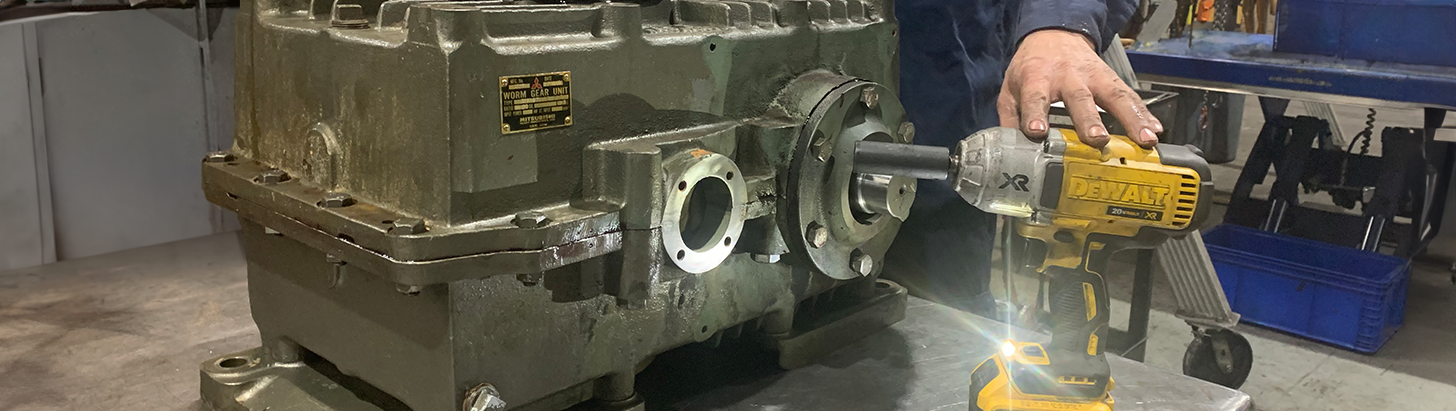

After

We consolidated the gearing into direct-driven motors and gearboxes, with custom baseplate stands for stability and organization.

Gearbox Repair Procedures and Practices

What Can You Expect From Our Gearbox Services?

Leveraging our expertise and state-of-the-art repair shop, Apex ensures that each gearbox repair is conducted with precision and attention to detail. Focusing on customer satisfaction, we strive to deliver timely and effective solutions that meet your specific needs and exceed your expectations.

Discover the Apex difference for gearbox repairs, where quality and efficiency are at the forefront of everything we do. Our commitment to excellence is reflected in our ability to diagnose and resolve complex gearbox issues, ensuring the longevity and reliability of your machinery.

Apex Industrial Automation provides an extensive gearbox repair service that covers a variety of procedures to guarantee your gearbox is returned to its best condition. Our service includes:

1. Pickup Service:

- Apex offers convenient pickup of your gearbox from your location.

2. Initial Inspection and Documentation

- Our experts conduct a thorough external inspection for signs of damage, wear, or leaks.

- We document the gearbox specifications, including model, serial number, and any visible issues.

3. Disassembly and Cleaning:

- We meticulously disassemble the gearbox, labeling and organizing all components.

- We then thoroughly clean all parts using appropriate methods to remove oil, grease, and debris. This includes completely disassembling all speed reducers or assemblies and utilizing a heated tank to ensure a deep clean of the components.

4. Component Inspection and Testing:

- Our experts inspect gears, shafts, bearings, and housings for wear, damage, or distortion.

- They measure critical dimensions and compare them with original specifications or manufacturer's tolerances.

- Cases, housings, shafts, and gearing are also visually inspected and dimensionally checked for possible reuse.

5. Quotation and Customer Approval:

- We provide a detailed quote outlining all necessary repairs, replacements, and associated costs, obtaining customer approval before proceeding with any repair work.

6. Gear Inspection and Repair:

- We inspect gears for wear, pitting, or breakage and repair or replace them as necessary to ensure proper fit and alignment.

- Gearing will be dimensionally inspected according to customer prints, manufacturers' prints, or reverse-engineered.

7. Bearing Replacement:

- Worn or damaged bearings are replaced with new, high-quality bearings, ensuring proper lubrication and seating for smooth operation.

8. Shaft Inspection and Repair:

- Shafts are inspected for wear, straightness, and alignment, with repairs or replacements made as needed to ensure proper fit and alignment with other components.

- Shafting repair may be made by plating and grinding or machining and sleeving.

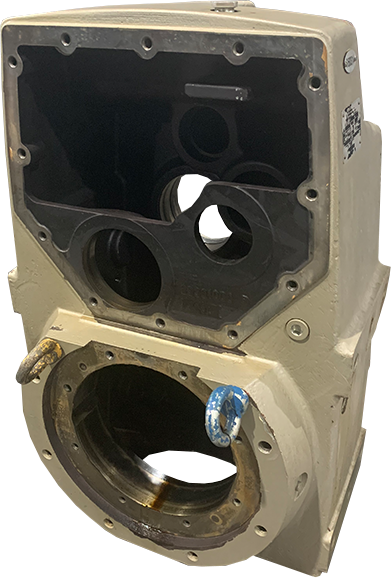

9. Housing Repairs:

- We inspect housings for cracks, distortion, or wear, repairing or replacing them as necessary to maintain structural integrity and proper alignment.

- All fits will be returned to their original size and relative centers using either sleeving and/or welding and machining as approved by the customer.

10. Seals and Gaskets Replacement:

- All seals and gaskets are replaced to ensure leak-free operation, with proper fit and installation verified for all sealing components.

11. Reassembly and Final Testing:

- The gearbox is reassembled, ensuring all components are correctly positioned and secured.

- Final testing is performed, including backlash measurement, noise and vibration analysis, and leak tests, to verify proper operation.

- All repaired and overhauled units will be run-tested to check contact patterns, clearances, backlash, and freedom of movement.

12. Painting and Identification:

- The gearbox housing is cleaned and painted with a protective coating, and a new identification tag with relevant repair information and specifications is applied.

13. Packaging and Shipment:

- Sensitive components and openings are protected during packaging, and the gearbox is securely packaged for safe transport with clearly marked handling instructions.

14. Delivery:

- The repaired gearbox is delivered back to you and is ready for operation.

With a focus on customer satisfaction, Apex Industrial Automation provides cost-effective and timely repairs supported by our extensive experience and expertise in the field. Apex is your partner in maintaining the performance and efficiency of your gearboxes and keeping your operations running smoothly and effectively.

Choose Apex Industrial Automation for all your gearbox repair needs, and experience peace of mind by partnering with a leader in industrial repair services.

Types of Gearboxes Repaired

Helical Gearbox Repair

With angled teeth for smoother operation, helical gearboxes are expertly repaired by Apex to ensure high-speed applications run efficiently and quietly. Our helical gearbox repair services deliver enhanced performance, directly benefiting your production efficiency.

Spur Gearbox Repair

Apex's repair services for spur gearboxes feature straight teeth parallel to the axis, which enhance their reliability in low-speed, high-torque applications. You'll experience improved torque transmission and extended equipment lifespan by choosing Apex for spur gearbox repairs.

Planetary Gearbox Repair

Compact and efficient, Apex meticulously repairs planetary gearboxes, ensuring optimal power distribution with their unique sun and planet gear configuration. Our planetary gearbox repair solutions offer superior torque handling and compact design advantages, optimizing your machinery's performance.

Worm Gearbox Repair

Specializing in worm gearbox repairs, Apex ensures these compact systems, known for high reduction ratios, operate smoothly in applications requiring significant speed reductions. Trust Apex to restore your worm gearboxes to peak efficiency, providing you with precise speed control and durability.

Spiral Bevel Gearbox Repair

Apex's skilled technicians repair spiral bevel gearboxes, which transmit power smoothly between non-parallel, intersecting shafts with their curved teeth design. Benefit from our spiral bevel gearbox repair services for quieter operation and improved power transmission in your machinery.

Hypoid Gearbox Repair

For hypoid gearboxes, Apex provides expert repairs, ensuring smooth operation and high torque transmission with their offset gear axes. Our hypoid gearbox repairs enhance your equipment's performance with superior load distribution and smooth power transfer.

Parallel-Shaft Gearbox Repair

Apex ensures reliable operation in various industrial applications by repairing parallel-shaft gearboxes, which transmit power in a straight line with gears arranged on parallel shafts. With our parallel-shaft gearbox repair expertise, you'll enjoy consistent power transmission and reduced maintenance costs.

Legacy Gearbox (Retrofit) Repair

Apex excels in retrofitting and repairing legacy gearboxes, updating older models to meet current performance standards and extend their service life. Opt for our legacy gearbox retrofit services to modernize your equipment, ensuring it meets today's efficiency and reliability standards.

Certifications and Standards

Redefining Excellence in Gearbox Repair

At Apex Industrial Automation, our gearbox repair services are setting a new benchmark for quality. We hold industry certifications and engage in partnerships with leading repair and distribution associations, demonstrating our unwavering commitment to delivering exceptional repairs. These collaborations are a testament to our dedication to continuously innovating and improving our industrial maintenance services for gearboxes.