Experience Reliable Onsite Repair & Maintenance

Rapid and Comprehensive Onsite Repair & Maintenance Services to Keep Your Business Moving.

Onsite Repair & Maintenance Services

Welcome to Apex Industrial Automation, your trusted partner for comprehensive onsite repair and maintenance solutions. We specialize in keeping your operations running smoothly with minimal downtime. Our expert team is equipped to handle all your repair and maintenance needs, delivering fast, efficient, and reliable services right at your doorstep.

Experience the peace of mind that comes with knowing your equipment is in capable hands.

Need Assistance?

Why Choose Apex for Onsite and Field Service Repair and Maintenance?

Apex Industrial Automation is a leading onsite and field service repair and maintenance provider. Our commitment to excellence, coupled with our unique position as a distributor, enables us to deliver cost-effective and superior service solutions.

Here’s why Apex is the smart choice for your onsite repair and maintenance needs:

Customer-Centric Approach

At Apex, every customer is a priority. We focus on providing customized solutions and exceptional service to ensure your complete satisfaction.

24/7 Emergency Support

Our emergency repair service is available around the clock to reduce downtime and keep your operations running smoothly.

Distributor Advantage

As a distributor, we can source replacement and repair parts at a lower cost, providing economical solutions that many of our competitors cannot match.

Local Presence in Illinois

Our strategically located repair shop ensures prompt and efficient service.

Full-Service Repair Shop

Our integrated repair and machine shop can handle everything from simple fixes to complex overhauls.

Quality Parts

We use only manufacturer-specified replacement parts or better to maintain your equipment’s integrity and optimal operation.

Expert Team

Our experienced and dedicated staff offers personalized service and expert guidance to ensure your success.

Onsite Services

Apex provides immediate and convenient onsite repair, installation, and maintenance services to minimize downtime.

Competitive Pricing

We offer competitive pricing for our repair services, ensuring you get the best value for your investment.

One-Year Warranty

We offer a one-year warranty on parts for our repairs, giving you confidence in the quality of our service.

Customized Maintenance Plans

We offer tailored maintenance plans to meet your specific operational requirements, ensuring proactive and preventive care.

Top-of-the-Line Equipment

We utilize industry-leading equipment to provide the most accurate and reliable repair results.

Comprehensive Repair Standards

Our adherence to high standards is demonstrated by our certifications and memberships, including EASA and UL, guaranteeing excellence and safety across all our repair services.

Advanced Technology Integration

We use cutting-edge technologies like IoT sensors and predictive analytics to enhance your maintenance strategy.

Custom Fabrication and Machining

We provide custom services to create or repair parts for unique or outdated equipment.

Specialized Repair Capabilities

Our expertise extends to servicing a wide range of equipment, ensuring optimal performance even in specialized applications.

Sustainability Practices

Our commitment to sustainability is reflected in our cost-saving and waste-reducing retrofitting services, which breathe new life into old equipment.

Training and Education

We provide comprehensive training and education services to empower your staff with the necessary knowledge and skills.

Engineering Support

Our team offers engineering support for system design, optimization, and troubleshooting.

Remote Support Capabilities

We offer remote support and diagnostics to quickly resolve minor issues without needing an onsite visit.

Precision In-House Machining

Our in-house machining capabilities ensure quick turnaround times and accurate repairs.

Industry Affiliations

As a member of SupplyForce, Power Transmission Distributors Association (PTDA), and Affiliated Distributors (AD), we are connected to a vast network of resources and expertise.

Scalable Solutions

Our repair and maintenance solutions can grow and adapt with your business needs.

Long-Term Partnerships

We are dedicated to building long-term partnerships, focusing on ongoing support and continuous improvement of your maintenance strategy.

Trust Apex Industrial Automation for all your onsite and field service repair and maintenance needs. Our commitment to quality and customer satisfaction ensures your operations run smoothly. Our skilled technicians provide fast, effective solutions directly at your location, minimizing downtime and disruption.

We offer a range of services, from emergency repairs to routine maintenance, using the latest equipment and techniques. Apex Industrial Automation is your reliable partner for keeping your machinery operating efficiently.

Onsite Procedures and Practices

Here's What You Can Expect From Our Specialized Services

Apex Industrial Automation offers a broad range of onsite repair and maintenance services to ensure your equipment operates at peak efficiency. Our team of skilled technicians is equipped to handle a wide range of MRO (Maintenance, Repair, and Operations) needs, from recurring scheduled maintenance to emergency repairs.

Here’s what you can expect from our onsite services:

1. Initial Site Assessment and Documentation:

- Our experts conduct a thorough assessment of your equipment and environment, documenting all relevant details to tailor our approach to your specific repair and maintenance needs.

2. Safety and Preparation:

- Safety is our top priority. We adhere to all safety protocols, including lockout/tagout procedures and PPE usage.

- We also prepare the work area with the necessary tools and equipment for the job.

3. Diagnostic and Inspection:

- Our team uses advanced diagnostic tools to identify the root cause of any issues.

- We inspect components for wear or damage, ensuring a comprehensive evaluation.

4. Quotation and Customer Approval:

- We provide a transparent quotation for the required work, ensuring you have all the details before we proceed with the customer's approval.

5. Emergency Repairs (If Required):

- If your equipment faces urgent issues, our team is ready to respond swiftly, minimizing downtime and restoring functionality.

6. Custom Field Service Work:

- Depending on the type of field service work required, we offer custom repair and maintenance solutions tailored to your specific needs and challenges.

7. Component Repair or Replacement (If Required):

- Damaged components are repaired or replaced with high-quality parts to ensure smooth operation and reliability.

8. Lubrication and Adjustments (If Required):

- Proper lubrication and adjustments are made to maintain optimal performance and prevent premature wear when applicable. This includes cleaning all components and applying appropriate lubricants to ensure smooth operation.

9. Performance Optimization:

- We optimize your equipment's performance to enhance efficiency and productivity, leveraging our expertise in system integration to ensure all components work harmoniously.

10. Testing and Verification:

- We conduct functional tests to verify that repairs and maintenance have been successful, making further adjustments as needed.

11. Safety and Performance Inspections (Optional):

- Regular safety and performance inspections can be scheduled to ensure compliance with industry standards and regulations.

12. Scheduled Maintenance (Optional):

- After repairs, we offer regular maintenance services to prevent breakdowns and extend the lifespan of your equipment, scheduled at your convenience.

13. Documentation and Reporting:

- A detailed service report is provided, documenting all work performed and offering recommendations for future maintenance.

14. Customer Walk-Through and Training:

- We offer a walk-through of the work performed and provide training on proper operation and maintenance practices.

15. Follow-Up and Support (Optional):

- We schedule follow-up visits and provide ongoing support to ensure your equipment continues to operate efficiently.

16. Additional Onsite Services (If Required):

- Full System Integration.

- Drive system installation and startup.

- Electrical and mechanical installation.

- Shaft current detection.

- Motor Electrical Testing.

- Control panel design, build, and installation.

- Laser shaft alignment and belt alignment.

- Vibration analysis using smart sensors and IIoT technology, such as Dodge OPTIFY.

- And more...

Our commitment to clear communication, adherence to environmental regulations, and proper disposal of waste materials ensures a seamless and responsible service experience.

Contact Apex Industrial Automation for all your onsite repair, maintenance, and system integration needs, and let us help you maintain optimal equipment performance.

Otis Spunkmeyer Testimonial

Minimizing Downtime with Apex's Exceptional Onsite Services

“Since Apex Industrial Automation started servicing our bakery, we’ve kept our downtime to a minimum, thanks to their staff always answering the call and going beyond the call of duty at all hours of the day and night. Our facility has machines that cost us thousands of dollars an hour in product output.

As a result, Apex is more than just the first place we call; they are the ONLY place we call to get our machines back up and running. Their dedication and reliability are unmatched.”

– Nick Alvertos

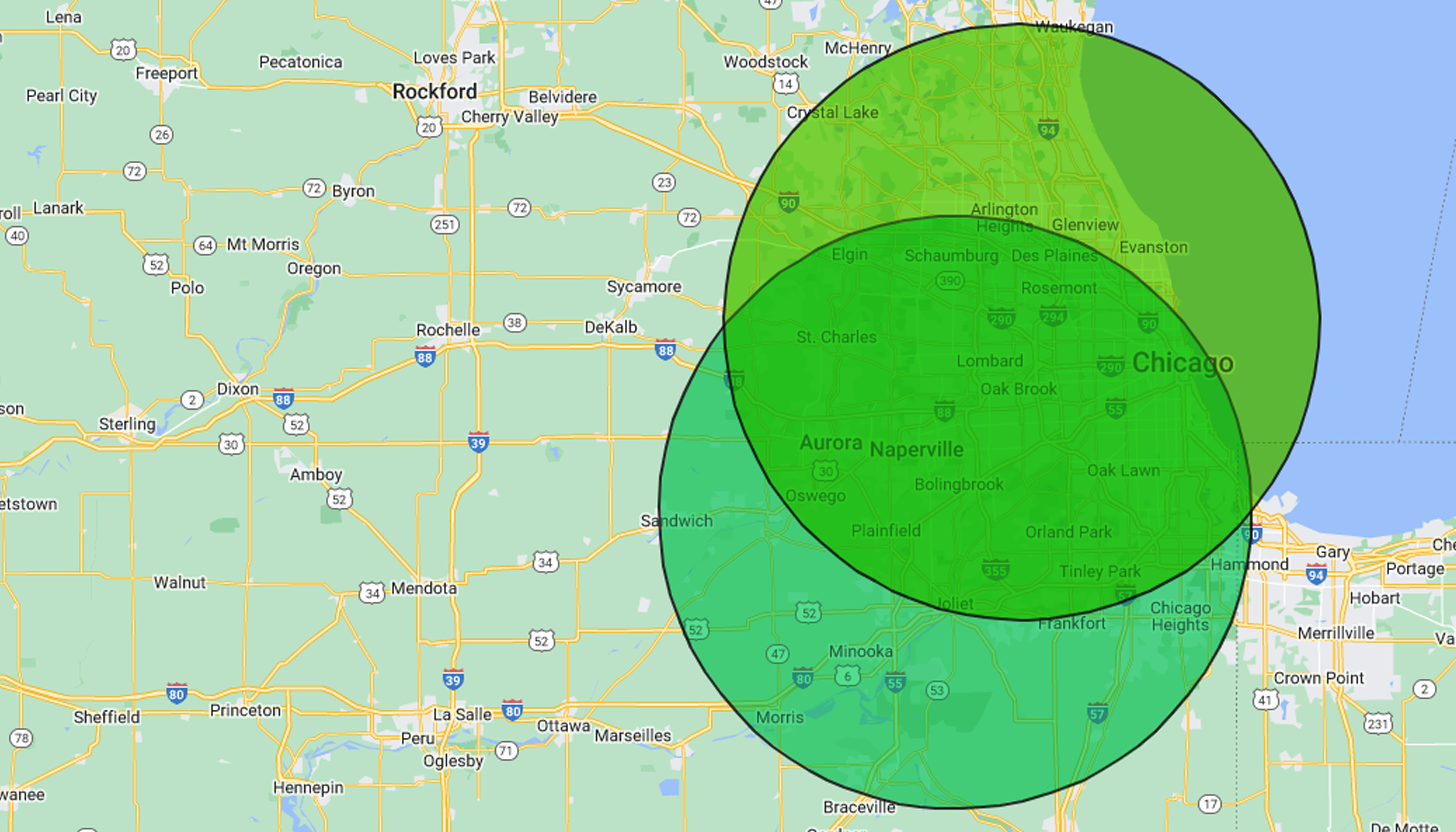

Service Area

Service Area Map

Your Local Onsite Repair Partner

Apex Industrial Automation is committed to providing our customers with prompt and efficient onsite repair and maintenance services. Our primary service area extends 30 miles in any direction from our locations, ensuring quick response times and minimal downtime for your operations. We’re willing to travel further for larger projects to meet your needs.

Don’t hesitate to contact us if you’re uncertain whether your location falls within our service area. Our friendly staff is here to assist you and provide any needed information. We are dedicated to our local community and committed to ensuring your equipment operates at its best.

For reliable and convenient onsite repair and maintenance services, trust Apex Industrial Automation.

Contact us today to discover how we can support your business within our service area.

Certifications and Standards

Excellence in Onsite Services

At Apex Industrial Automation, our commitment to quality and safety is at the forefront of our onsite repair and maintenance services.

We uphold the highest industry certifications and standards to ensure that our services not only meet but exceed your expectations.