Expert AC/DC Electric Motor Repair Solutions

Experience Cutting-Edge Electric Motor Repair with Our Certified EASA Technicians.

Experience the Apex Difference in AC/DC Electric Motor Repair!

At Apex Industrial Automation, we’re not just about quick fixes; we’re your partners in maintaining peak performance. Our expert team in our EASA-certified shop is equipped with cutting-edge technology and examines your Alternating Current (AC) or Direct Current (DC) electric motor to diagnose and resolve issues efficiently. With Apex, you get electric motor repair that enhances your motor’s performance and productivity.

Ready to experience unparalleled efficiency and expertise in repair?

Need Assistance?

Why Choose Apex for Electrical Motor Repair?

Choosing Apex Industrial Automation for your motor repair needs means selecting a partner dedicated to excellence, reliability, and customer satisfaction.

Here’s why Apex stands out in the industry:

EASA Accredited

We follow the latest Electrical Apparatus Service Association (EASA) repair guidelines, AR100-2020. As one of only eight shops in Illinois accredited by EASA, Apex ensures the highest standards and best practices in motor repair.

UL Certified Motor Repair

Our UL certification guarantees excellence in motor repair for all locations, including Hazardous Locations; Class 1, Division 1 – Groups C & D and Class II, Division 1 – Groups E, F & G.

ANSI Repairs

We adhere to the American National Standards Institute (ANSI) guidelines for all repairs, ensuring that every motor we service meets the stringent quality and safety standards set by this respected organization.

24/7 Emergency Services

Our around-the-clock emergency repair service is always ready to address your electric motor issues, ensuring minimal downtime.

Full-Service Shop

As a leader in electric motor and related equipment repair, our integrated repair and machine shop is equipped to handle all your needs.

Local Presence

We ensure prompt and efficient service with two conveniently located repair shops in Northern Illinois.

Two-Year Warranty

We stand behind our work with a two-year repair warranty, providing you with peace of mind.

Top-of-the-Line Equipment

Our industry-leading test equipment, including Advanced Winding Analyzers, Megger/Scope Testing, and Vibration Tests, ensures the most accurate and reliable repair results.

Quality Parts

We use only manufacturer-specified replacement parts or better, including premium brand Class N insulation and top-quality bearings and seals, to ensure your motor’s reliability and longevity.

Expert Team

Our experienced and committed staff is dedicated to your success, providing personalized service to meet your unique needs.

Customer-Centric Approach

At Apex, every customer is a priority. We focus on providing customized solutions to ensure your satisfaction.

Competitive Pricing

We offer competitive pricing to minimize your downtime and keep your operations running smoothly.

At Apex Industrial Automation, we’re committed to delivering superior AC/DC electric motor repair services that not only fix your immediate issues but also enhance your motors’ overall performance and lifespan. When you choose Apex for motor repair, you choose a partner committed to providing you with the best possible service and results.

Trust Apex to keep your operations running smoothly and efficiently.

Advanced Winding Analyzer

Apex utilizes an advanced winding analyzer to ensure the integrity and performance of motor windings.

Documented Megger/Scope Testing

We provide documented Megger/scope testing to assess your motors' insulation quality and electrical safety.

Handheld Megger

Our technicians use handheld Meggers for quick and accurate insulation testing on the go.

Resistance Test

Apex conducts resistance tests to evaluate the electrical resistance of motor components, ensuring optimal performance.

Hipot Test

We perform Hipot tests to check the insulation strength and detect any potential breakdowns in your electrical equipment.

Surge Test

Our surge testing identifies motor windings and insulation weaknesses, preventing future failures.

Written Repair & Replacement Quotes

Apex provides detailed written quotes for all repair and replacement services, ensuring transparency and accuracy.

Premium Brand Class N Insulation with 2-Year Warranty

We use premium brand Class N insulation for superior thermal resistance, backed by a 2-year warranty.

Bearings & Seals with 1-Year Warranty

Apex offers top-quality bearings and seals with a 1-year warranty for reliable and smooth motor operation.

Core Loss Testing (Before and After Burnout)

We conduct core loss testing before and after burnout to assess the condition of your motor's core and ensure its efficiency.

Dynamic Balancing

Our dynamic balancing service corrects imbalances in rotating components, reducing vibration and extending equipment life.

Test Run

Apex performs test runs to verify the proper functioning and performance of repaired or newly installed equipment.

Vibration Test

We conduct vibration testing to detect and diagnose issues in rotating machinery, ensuring smooth operation.

Assembly of Equipment Back to OEM Specs

Apex assembles equipment back to OEM specifications, guaranteeing original performance and reliability.

AC/DC Electric Motor Repair Procedures and Practices

Here's What You Can Expect From Our Specialized Services

At Apex Industrial Automation, we follow a meticulous repair process for AC/DC electric motors, aligning with the esteemed ANSI/EASA Standard AR100-2020. This approach ensures our services not only meet but often exceed industry benchmarks for quality and reliability.

Apex ensures your motors operate efficiently and reliably. Our process includes the following steps:

1. Pickup Service:

- We make it easy for you by offering a convenient pickup service for your AC/DC motor from your location.

2. Initial Inspection and Disassembly:

- We start by thoroughly inspecting the motor for any external damage or wear.

- Then, we carefully disassemble the motor, making sure all parts are accounted for and properly labeled for reassembly.

3. Initial Assessment:

- Our experts conduct a thorough assessment, including a mugger test, to determine the condition of your motor.

4. Cleaning and Stripping:

- We clean all components using appropriate methods to remove grease, dirt, and debris.

- If rewinding is necessary, we strip the insulation from the windings.

5. Component Inspection and Testing:

- We inspect all mechanical components like bearings, shafts, and housings for wear and damage.

- We test electrical components like windings and capacitors for continuity, resistance, and insulation integrity.

- We also perform advanced testing, including Winding Analyzer, Megger/Scope Testing, and more.

- All findings are documented, and we provide detailed reports with photos or sketches as needed.

6. Cause of Failure Analysis:

- We perform a detailed analysis, including a hipot test, to identify the root cause of failure.

7. Quotation and Approval:

- We prepare a detailed quotation listing all required repairs, replacements, and associated costs.

- We make sure to get your approval before proceeding with any repair work.

8. Cost-Effective Solutions:

- If repair costs exceed the replacement value, we offer replacement options to ensure cost-effectiveness.

9. Custom Repair Approach:

- We tailor the repair process to your motor's specific needs, including machining new shafts and gears if necessary.

10. Stator Core Inspection & Testing:

- We ensure the stator core is in optimal condition for efficient motor operation.

11. Windings:

- We rewind or replace windings as necessary, adhering to original specifications or customer-approved modifications.

- We use proper insulation and varnishing techniques to protect windings from heat and moisture.

12. Bearings and Shaft:

- We replace or repair bearings and shafts as needed, ensuring proper fits and tolerances for smooth operation.

13. Mechanical Components:

- We repair or replace gears, couplings, and other mechanical components as required.

- We ensure proper alignment and balance of all rotating components.

14. Electrical Components:

- We replace or repair faulty electrical components such as capacitors, brushes, and switches.

- We ensure proper electrical connections and insulation.

15. Reassembly and Testing:

- We carefully reassemble the motor, ensuring all components are properly aligned and secured.

- We perform a series of tests to ensure the motor is operating correctly.

16. Final Inspection & Testing:

- We conduct a comprehensive final inspection and testing to ensure the motor meets our high standards.

17. Calibration & Validation:

- We calibrate and validate your motor for optimal performance.

18. Painting and Identification:

- We clean and paint the motor housing with a protective coating.

- We attach a new identification tag with relevant information.

19. Packaging and Shipment:

- We protect all openings and delicate parts with appropriate covers or plugs.

- We package the motor securely for shipment, ensuring it is clearly marked with handling instructions.

20. Delivery:

- We deliver the repaired motor back to you, ready for operation.

By adhering to the ANSI/EASA AR100-2020 standards, Apex Industrial Automation guarantees that each AC/DC electric motor repair we undertake is executed with precision, care, and a focus on long-term reliability and efficiency. Our commitment to these standards reflects our dedication to providing superior service and ensuring customer satisfaction.

Suncast Testimonial

Speedy Solutions That Save Time and Money

“At Suncast, we faced a daunting 12-week wait for repairs on an OEM motor from overseas. That’s when Apex Industrial Automation stepped in and transformed our situation. Their team expertly retrofitted an off-the-shelf motor, tailoring it to our needs with a custom base plate, new bearings, and a blower.

What truly set Apex apart was its speed and efficiency. They completed this intricate retrofit within 2-3 days of receiving our order, exceeding our expectations. This swift turnaround saved us significant time and reduced our costs. Choosing Apex meant partnering with a company that truly understands the value of time and money in business.

Their skill in delivering fast, cost-effective, and customized retrofitting solutions is why we trust Apex for our engineering needs.”

– Juan Delagado

Authorized Repair Service Center

Excellence in AC/DC Electric Motor Repair

Apex Industrial Automation is an authorized service center showcasing our commitment to exceptional motor service and repair. Our authorizations from various high-end motor manufacturers are a mark of trust and competency.

We focus on delivering efficient, reliable, and technically sound service solutions that extend your motor’s lifespan and optimize its performance.

And Many More…

Certifications and Standards

Ensuring Industry-Best Repairs

Apex Industrial Automation sets the standard in electric motor repair, backed by our industry certifications and associations.

These strategic partnerships affirm our commitment to quality and innovation in industrial maintenance.

Electrical Apparatus Service Association (EASA)

As a member of the Electrical Apparatus Service Association (EASA), we uphold the highest standards in electric motor repair. Our accreditation with EASA, a leader in this domain, ensures our repairs meet and often exceed rigorous industry benchmarks. Apex is recognized as one of the select few EASA-accredited shops in Illinois, highlighting our expertise in the Chicagoland area.

UL-Certified Repairs

Our UL-certification and UL-674 certification showcase our advanced capabilities in electric motor repair. These rigorous standards ensure the safety and reliability of electric motors and generators in these critical settings.

Class 1, Division 1 – Groups C & D: We are proficient in handling equipment in environments where flammable gases or vapors may be present, ensuring that repairs meet the stringent safety requirements for these high-risk areas.

Class II, Division 1 – Groups E, F & G: Our expertise extends to environments with combustible dust, where maintaining safety standards is crucial. This includes various industrial settings, ensuring our repair services cater to hazardous conditions.

SIEMENS Authorized Regional Repair Center

As an Authorized Regional Repair Center for Siemens, we offer specialized maintenance services for Siemens motors. Our advanced facilities and skilled team ensure each repair maintains the integrity and performance of your Siemens equipment.

Preventative Maintenance

Apex Industrial Automation's Unique Approach to Maintenance

At Apex Industrial Automation, our philosophy and approach to preventative maintenance set us apart from competitors. We understand that consistent production line operation is critical to your business’s success, and we’re dedicated to ensuring that your equipment runs smoothly without the frequent breakdowns that others might profit from.

Proactive, Not Reactive

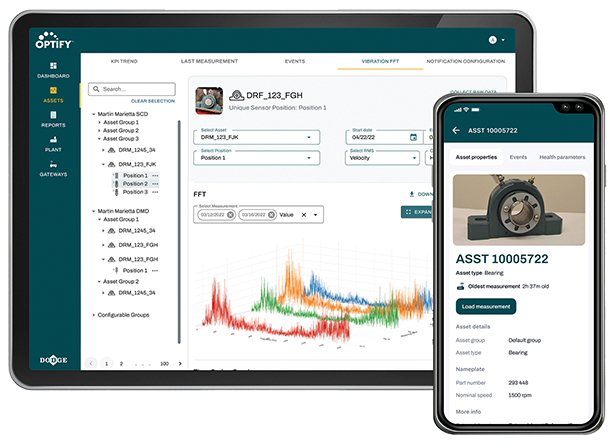

Our focus is on proactivity, unlike competitors who might benefit from repeated breakdowns and subsequent repairs. We utilize advanced technologies like Dodge OPTIFY™ and Intelli-Lube™ as part of our preventative maintenance strategy. These tools help us predict and prevent issues before they occur, ensuring your production lines run without interruption.

Dodge OPTIFY™

The Dodge OPTIFY™ platform allows you to monitor the condition of your equipment in real-time. By analyzing data such as vibration and surface temperature, you can anticipate maintenance needs and help avoid unplanned downtime.

Intelli-Lube™

Integrated with OPTIFY™, Intelli-Lube™ automates the lubrication process, consistently providing the correct amount of lubrication. This precision prevents over and under-lubrication, a common cause of equipment failure.

Extended Equipment Life

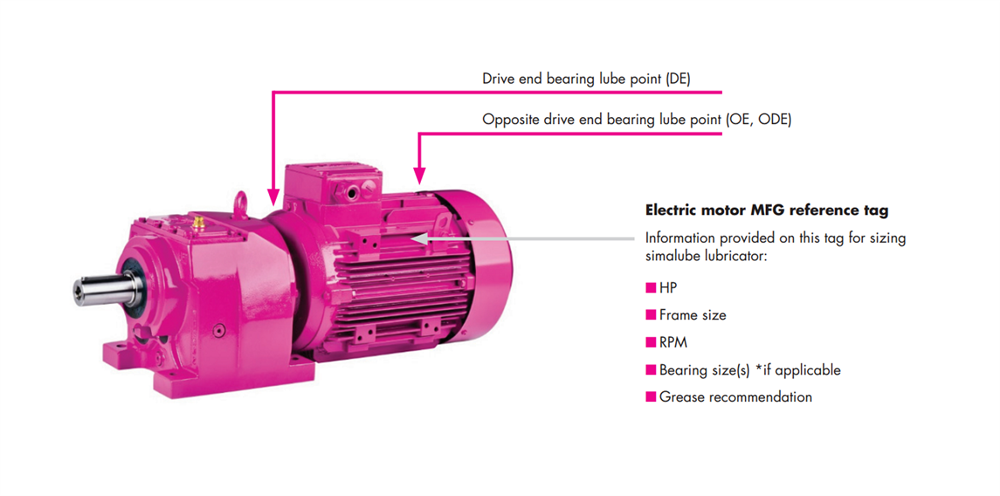

With tools like AEGIS® Shaft Grounding Rings and Simatec Automatic Lubricators, we extend the life of your machinery. These technologies protect against electrical and mechanical wear, two significant factors that can lead to breakdowns.

Customized Solutions

Our approach is not one-size-fits-all. We tailor our preventative maintenance strategies to your specific needs and operations. This personalized approach ensures that we address your production line’s unique challenges and requirements.

Simatec Automatic Lubricators

By choosing Apex Industrial Automation for your maintenance needs, you’re choosing a partner invested in your continuous operation and success. Our advanced preventative maintenance strategies are designed to keep your equipment running efficiently, reduce the likelihood of costly downtime, and ensure your production lines are always operational.