Precision Servo Motor Repair Solutions

Restore Your Servo Motors to Peak Performance with Apex’s Certified Repair Services.

Expert Servo Motor Repair Services for Optimal Performance

At Apex Industrial Automation, we understand the precision and performance required for servo motor operations. Our dedicated team, armed with advanced diagnostic tools and technology, delves deep into your servo motor to identify and rectify any issues, ensuring optimal functionality. With Apex, you receive servo motor repair services that fix the problem, enhance the performance, and improve the longevity of your motor.

Apex is here to ensure your operations run smoothly and precisely every time.

Need Assistance?

Why Choose Apex for Servo Motor Repair?

Apex Industrial Automation sets ourselves apart by focusing on key differentiators that ensure premium service and results for our clients.

Our commitment to excellence, state-of-the-art technology, and a customer-centric approach are just a few reasons why choosing Apex for servo motor repair is a smart decision for your business. Let us show you how our unique advantages can keep your servo motors running at peak performance.

EASA Accredited

Apex follows the latest Electrical Apparatus Service Association (EASA) repair guidelines, AR100-2020, and as one of only eight shops in Illinois accredited by EASA, we ensure the highest standards and best practices in servo motor repair.

ANSI Repairs

We adhere to the American National Standards Institute (ANSI) guidelines for all repairs, ensuring that every servo motor we service meets this respected organization’s stringent quality and safety standards.

Distributor Associations

As a distributor with strong industry associations, Apex leverages these partnerships to enhance the quality of our repairs. Our involvement with top-tier associations grants us access to an extensive array of parts and components from the best manufacturers globally.

24/7 Emergency Services

Our around-the-clock, 24/7 emergency repair service is always at your disposal to minimize downtime and keep your operations running smoothly.

Full-Service Shop

As a leader in servo motor and related equipment repair, our integrated repair and machine shop is equipped to handle all your needs with precision.

Local Presence

With a strategically located repair shop in Northern Illinois, we ensure quick and efficient service to keep your operations uninterrupted.

Two-Year Warranty

We offer a two-year warranty on our standard servo motor rewinds, giving you confidence in the quality of our work.

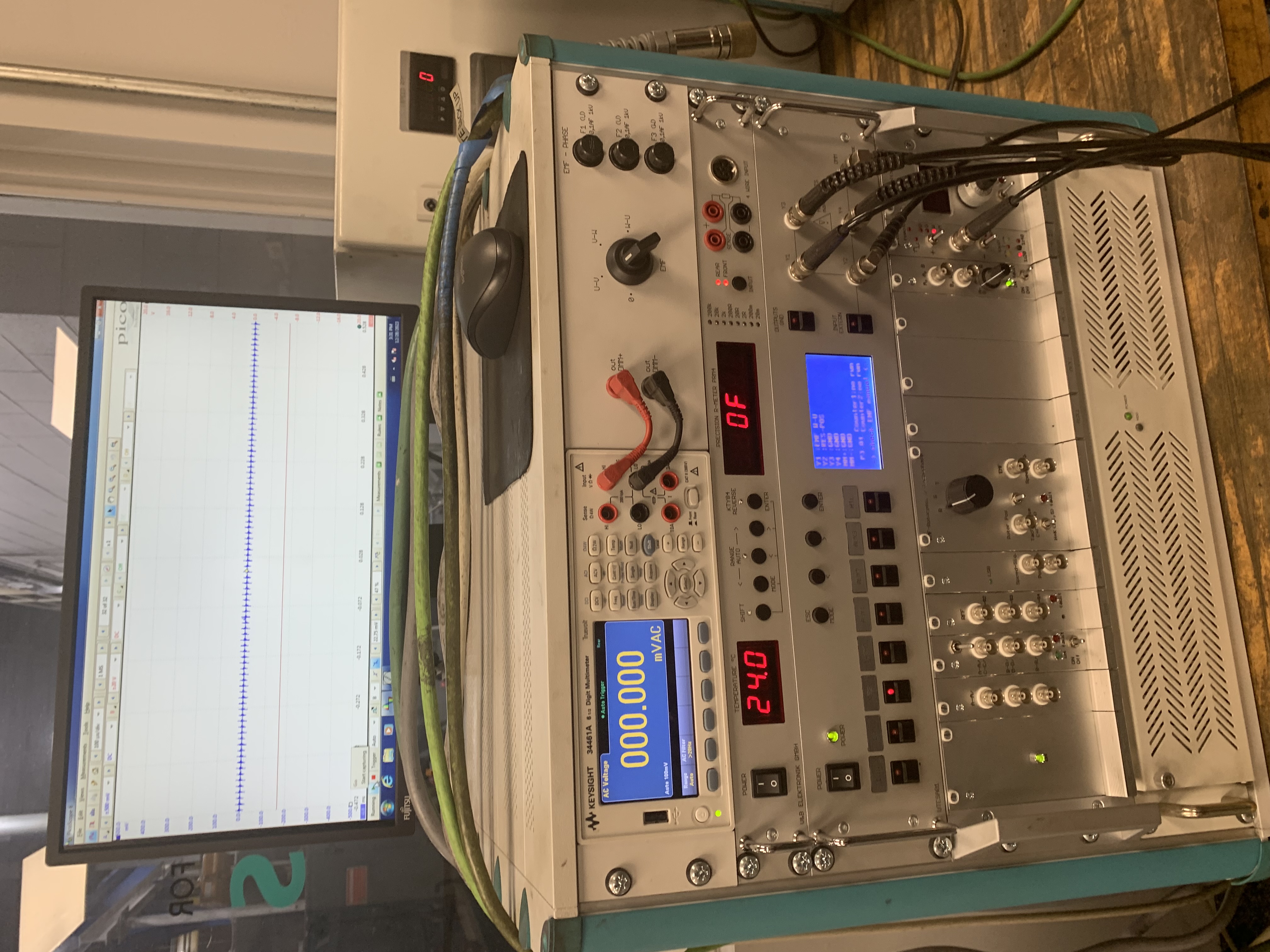

Advanced Diagnostic Equipment

Our state-of-the-art diagnostic equipment, including AlignMATE, RunWELL, LineaX3, and Octava Engineering, ensures accurate and reliable repair results.

Quality Parts

We use only manufacturer-specified replacement parts or better, including premium brand Class N insulation and top-quality bearings, to guarantee the reliability and longevity of your servo motor.

Expert Team

Our skilled and dedicated staff is committed to your success, offering personalized service to meet your unique requirements.

Customer-Centric Approach

At Apex, every customer is a priority. We focus on providing tailored solutions to ensure your complete satisfaction.

Competitive Pricing

We offer competitive pricing to minimize your downtime and ensure cost-effective repairs.

Apex Industrial Automation is dedicated to providing exceptional servo motor repair services that go beyond merely addressing immediate problems. Our aim is to improve the overall performance and lifespan of your servo motors. When you choose Apex for your servo motor repair needs, you’re selecting a partner that’s committed to delivering the highest quality of service and results.

Trust Apex to ensure your operations run with precision and efficiency.

AlignMATE

Precision alignment tool ensuring accurate servo motor feedback and control.

RunWELL

Advanced diagnostic system for comprehensive servo motor performance analysis.

LineaX3

State-of-the-art testing equipment for precise linear motion and feedback verification.

Octava Engineering Equipment

Specialized engineering solutions for complex servo motor challenges.

Mitchell TI-5000

Cutting-edge diagnostics for encoders, resolvers, and servo motor repairs.

ESD Mats

Essential safety measures to protect sensitive electronic components during repairs.

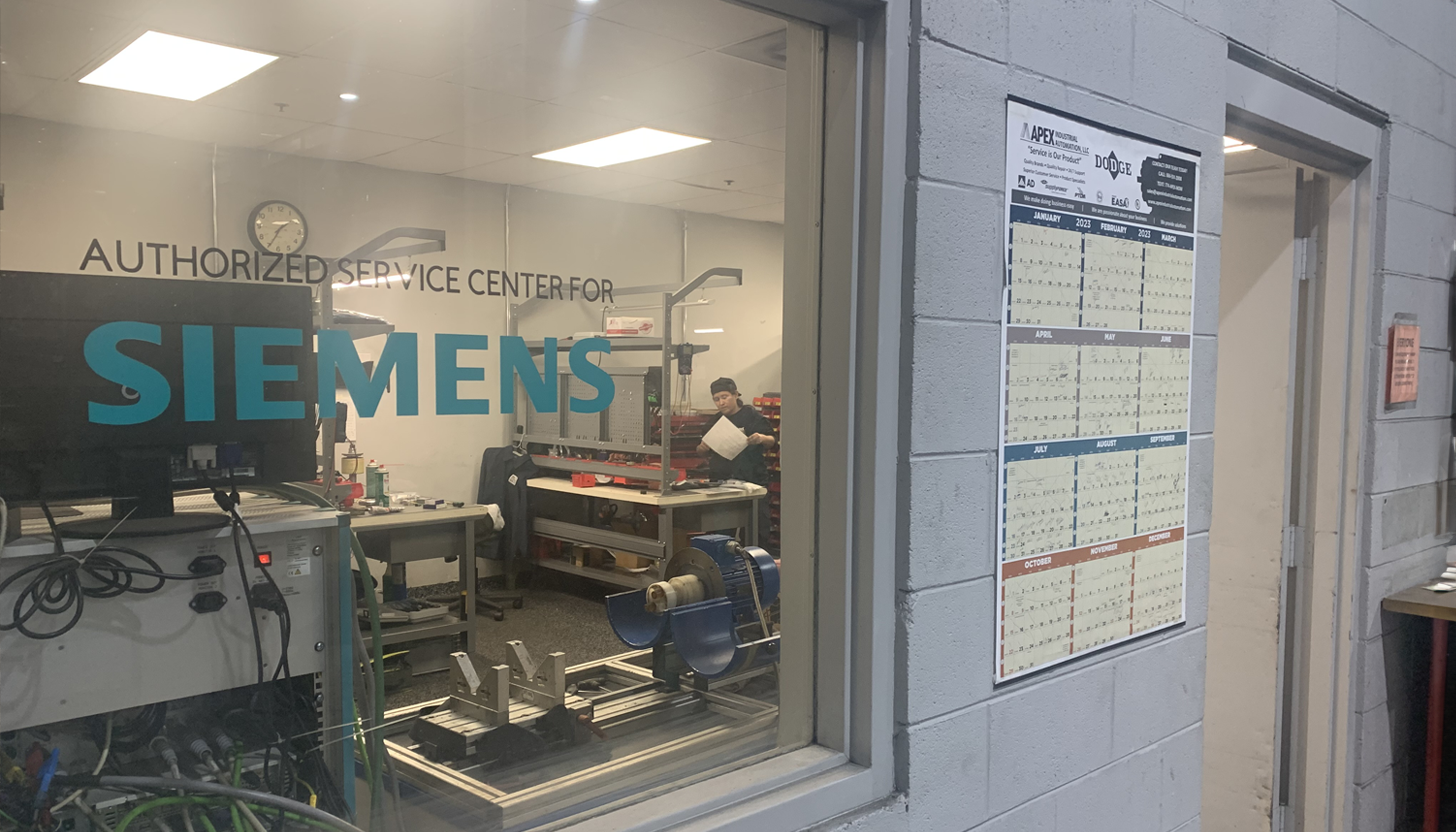

SIEMENS Lab

Climate-controlled, clean-room facility for precise diagnostics and repairs of SIEMENS servo motors.

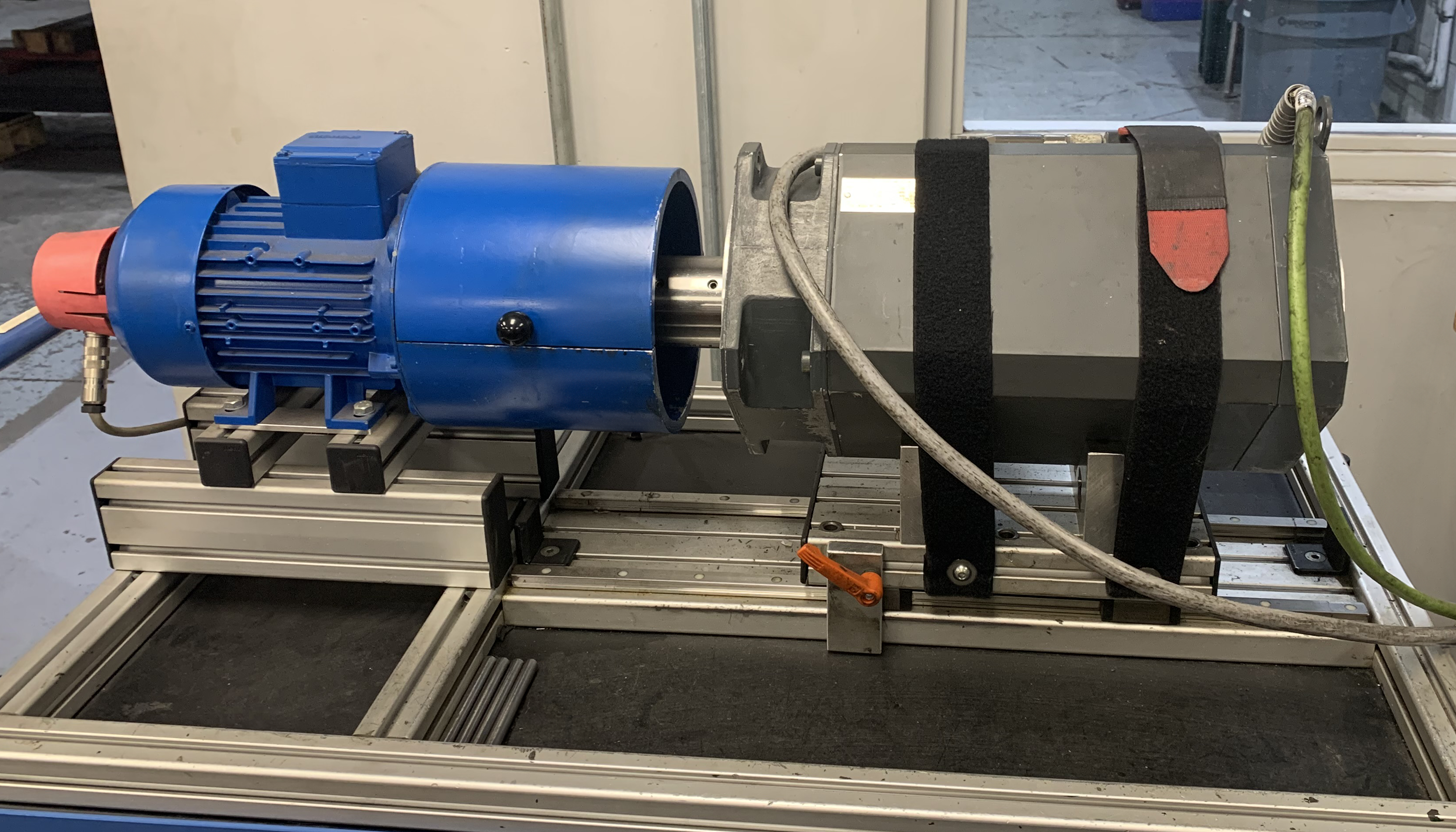

Onsite Rewinding

Unique capability to rewind servo motors onsite for quick and efficient repairs.

Standard Servo Motor Rewind

High-quality rewinds with inverter duty wire and Class N insulation, backed by a 2-year warranty.

Servo Motor Repair Procedures and Practices

What to Expect From Apex Servo Services

At Apex Industrial Automation, we pride ourselves on our comprehensive servo motor repair services, ensuring your equipment operates at peak performance. Our state-of-the-art testing equipment allows precise encoders, resolvers, and other component diagnostics.

Our Servo repair process includes:

1. Pickup Service:

- We offer convenient pickup of your servo motor from your location, ensuring a hassle-free start to the repair process.

2. Initial Inspection and Documentation:

- Our technicians conduct a thorough visual inspection for external damage or wear and document motor specifications, including model, serial number, and any visible issues.

3. Disassembly and Cleaning:

- We carefully disassemble the motor, labeling and organizing components for reassembly, and clean all parts using appropriate methods to remove contaminants and debris.

4. Component Inspection and Testing:

- We inspect mechanical components such as bearings, shafts, and housings for wear or damage and test electrical components like windings, encoders, and resolvers for proper function and integrity.

- All findings and measurements are meticulously documented for reference.

5. Diagnostic Testing:

- Our experts perform initial diagnostic tests to identify specific issues with the servo motor, including feedback alignment checks, using our advanced testing equipment like AlignMATE, RunWELL, LineaX3, and Octava Engineering.

6. Quotation and Customer Approval:

- We provide a detailed quotation outlining all necessary repairs, replacements, and associated costs and obtain customer approval before proceeding with any repair work.

7. Encoder/Resolver Alignment:

- We inspect and adjust encoders or resolvers for accurate position feedback, ensuring proper alignment and calibration for precise motor control.

8. Windings Repair or Rewinding:

- Our technicians are skilled in repairing or rewinding motor windings as needed, following manufacturer specifications or approved modifications.

- We use inverter duty wire and Class N insulation, allowing us to offer a 2-year warranty on our standard servo motor rewinds.

9. Bearing Replacement:

- We replace worn or damaged bearings with new, high-quality bearings, ensuring proper lubrication and seating for smooth operation.

10. Mechanical Repairs:

- We repair or replace damaged shafts, housings, and other mechanical components, ensuring all components are correctly aligned and balanced.

11. Electrical Repairs:

- Our team repairs or replaces faulty electrical components such as capacitors, connectors, and wiring and verifies proper electrical connections and insulation.

12. Feedback Device Repair:

- We specialize in repairing or replacing critical feedback devices, such as encoders and resolvers, to ensure precise motor control.

13. Electronic Component Repair:

- We can repair or replace electronic components, such as drives and controllers, integral to servo motor function.

14. Reassembly and Final Testing:

- We reassemble the servo motor, ensuring all components are correctly positioned and secured.

- Afterward, we perform comprehensive testing, including dynamic response tests, feedback alignment checks, and load tests, to verify proper motor performance.

15. Calibration & Validation:

- Your servo motor is calibrated and validated for accurate and efficient performance, ensuring it meets your operational requirements.

16. Painting and Identification:

- We clean and paint the motor housing with a protective coating and apply a new identification tag with relevant repair information and specifications.

17. Packaging and Shipment:

- We protect all sensitive components and openings during packaging and securely package the motor for safe transport, clearly marking handling instructions.

18. Delivery:

- We deliver the repaired servo motor back to you, ready for integration into your system.

Our repair facility is equipped with state-of-the-art testing equipment and a climate-controlled, clean-room environment to ensure the highest quality repairs. We maintain detailed records of all repair activities and test results, provide a warranty for the repair work, and clearly communicate the terms to our customers.

Certifications and Standards

Elevating Servo Motor Repair Excellence

At Apex Industrial Automation, we’re raising the bar for servo motor repair services. Our industry certifications and our collaborations with leading associations in the field reinforce our commitment to quality. These partnerships highlight our dedication to delivering top-notch repairs and reflect our continuous pursuit of innovation in industrial maintenance for servo motors.

Regional Repair Center for Siemens Servo Motors

Apex Industrial Automation is proud to be a Regional Repair Center for Siemens Simodrive motors. This designation underlines our commitment to delivering exceptional repair and maintenance services. Our state-of-the-art facilities, including an environmentally controlled Siemens lab with electro-static device (ESD) safe workbenches, ensure that every Siemens servo motor repair is conducted with the utmost precision and care, free from environmental contaminants.

Our team’s specialized skills, combined with our sophisticated environment, guarantee the highest quality of service, maintaining the integrity and performance of your Siemens equipment.

Quality Repairs for Leading Servo Motor Brands

Expert Servo Repairs for Top Manufacturers

Apex Industrial Automation is your go-to source for expert repair and maintenance services for various servo motors. Our service authorizations reflect a level of trust and expertise acknowledged by numerous leading servo motor manufacturers.

Apex is committed to providing efficient, dependable, and technically advanced service solutions to guarantee your servo motors’ longevity and peak performance.