Specialty Repairs: Precision for Unique Equipment Needs

Your Expert Partner in Unique Specialty Repair Needs.

Discover Apex's Excellence in Specialty Repairs!

At Apex Industrial Automation, we go beyond standard solutions to ensure your unique equipment operates at its peak performance. With over 70 years of experience, our skilled team handles all makes, models, and ages of equipment, providing specialized repairs that meet EASA standards. Whether at our facility or onsite, we pride ourselves on 100% customer satisfaction by restoring your equipment to its original specs, precision, and performance.

Ready to partner with a team that keeps your operations running smoothly? Apex is your trusted ally in specialty equipment repair and maintenance.

Need Assistance?

Why Apex Industrial Automation is the Best Choice for Custom Specialty Repairs

Apex Industrial Automation stands out as the leading provider of custom specialty repairs, offering unparalleled expertise, precision, and customer satisfaction. Our commitment to excellence in every aspect of our service ensures that your unique equipment is repaired to the highest standards, delivering optimal performance and reliability.

What sets Apex apart in Specialty Repair?

Expert Team

Our experienced professionals specialize in custom solutions, ensuring your equipment receives the attention and expertise it deserves.

Customer-Centric Approach

Every customer is a priority at Apex, and we focus on providing personalized solutions and exceptional service to ensure your complete satisfaction.

Industry Affiliations

As a member of SupplyForce, Power Transmission Distributors Association (PTDA), and Affiliated Distributors (AD), we leverage a vast network of resources and expertise to provide top-of-the-line service and support.

Specialized Capabilities

Our expertise covers a wide range of specialty repairs, from intricate components to complex mechanical systems.

Quality Parts

We use only the best replacement parts, meeting or exceeding manufacturer specifications, to maintain the integrity of your equipment.

State-of-the-Art Equipment

Our industry-leading tools and technology ensure precise and reliable repair results.

Onsite Services

We offer convenient onsite repair, installation, and maintenance services to minimize downtime and keep your operations running smoothly.

One-Year Warranty on Parts

Our one-year warranty on all parts used in repairs gives you confidence in the durability and reliability of our service.

Engineering Support

Our team provides engineering support for system design, optimization, and troubleshooting, ensuring efficient and reliable solutions for your specific needs.

Comprehensive Repair Standards

We adhere to the highest standards, and our certifications and memberships in EASA and UL guarantee excellence and safety in all our custom repairs.

Custom Fabrication and Machining

We can create or repair parts for unique or outdated equipment, ensuring optimal performance even when original parts are unavailable.

Two-Year Warranty on Motor Rewinds

For specialty motor repairs, we stand behind the quality of our motor rewinds with a two-year warranty, ensuring your peace of mind and confidence in the longevity and reliability of your repaired motor.

Industry Affiliations

As a member of SupplyForce, Power Transmission Distributors Association (PTDA), and Affiliated Distributors (AD), we leverage a vast network of resources and expertise to provide top-of-the-line service and support.

When you choose Apex Industrial Automation for your custom specialty repairs, you choose a partner dedicated to your success. Our comprehensive approach, from expert consultation to precision reassembly and testing, ensures that your equipment is restored to its original specifications, precision, and performance.

Rely on Apex to keep your operations running smoothly and efficiently with our expert specialty repair solutions.

Apex can repair many types of industrial machinery.

We’re your partner in specialty industrial repairs, from Chicago bridge motors to custom assembly line machinery to embedded magnetic-rotor motors.

Specialty Repair Case Study:

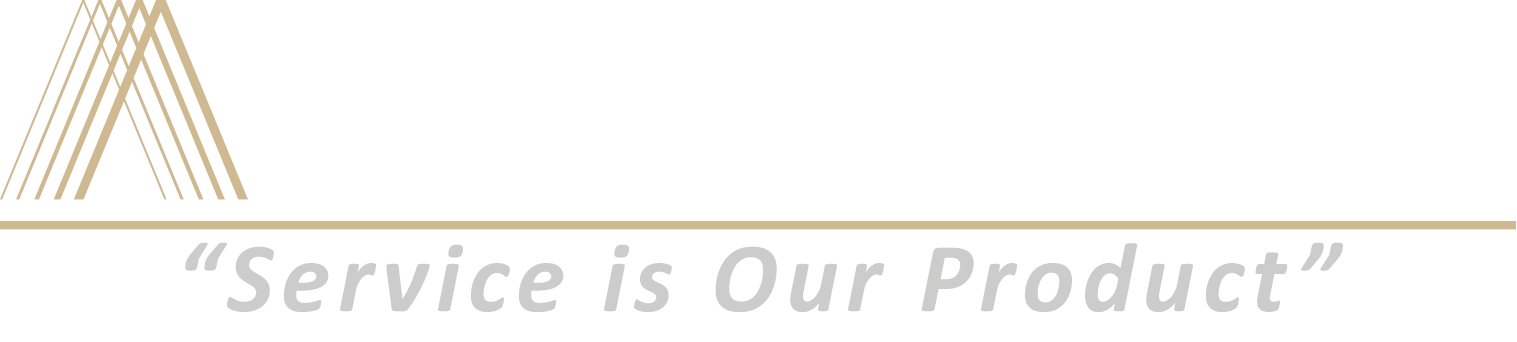

Custom Industrial Blender Overhaul

Customer Challenge

A global food and beverage manufacturing company approached Apex Industrial Automation with a unique challenge: their custom industrial blender, critical to their production line, needed a significant overhaul. The old motor was underperforming, their old control panel didn’t meet the required safety standards, and a gearbox was necessary to enhance the machine’s efficiency and reliability.

Apex Solution

Our team at Apex embarked on a comprehensive repair and upgrade process to breathe new life into the industrial blender. The first step involved carefully removing the legacy motor, which had become a bottleneck in the machine’s operation. In its place, we installed a new, high-performance motor tailored to meet the demanding requirements of the food manufacturing industry.

Understanding the importance of precision in such a specialized piece of equipment, our engineers crafted a custom baseplate. This custom component ensured the new motor was securely mounted and perfectly aligned within the blender’s framework.

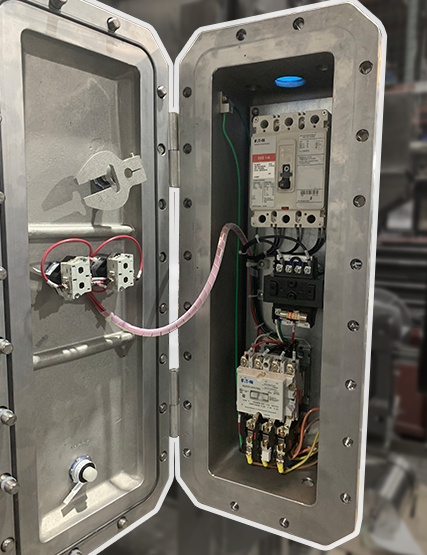

New Gearbox

We introduced a gearbox into the system to enhance the machine’s functionality. This addition was pivotal in optimizing the blender’s speed and torque, improving its overall performance. The gearbox was installed with precision, ensuring that it worked in harmony with the new motor.

Laser Aligned Belt

Alignment was a critical factor in this repair, especially with the introducing of new components. Our team utilized a belting laser alignment tool to guarantee a flawless connection between the new motor and the equipment. This state-of-the-art technology ensured the belt was perfectly aligned, minimizing wear and tear and maximizing efficiency.

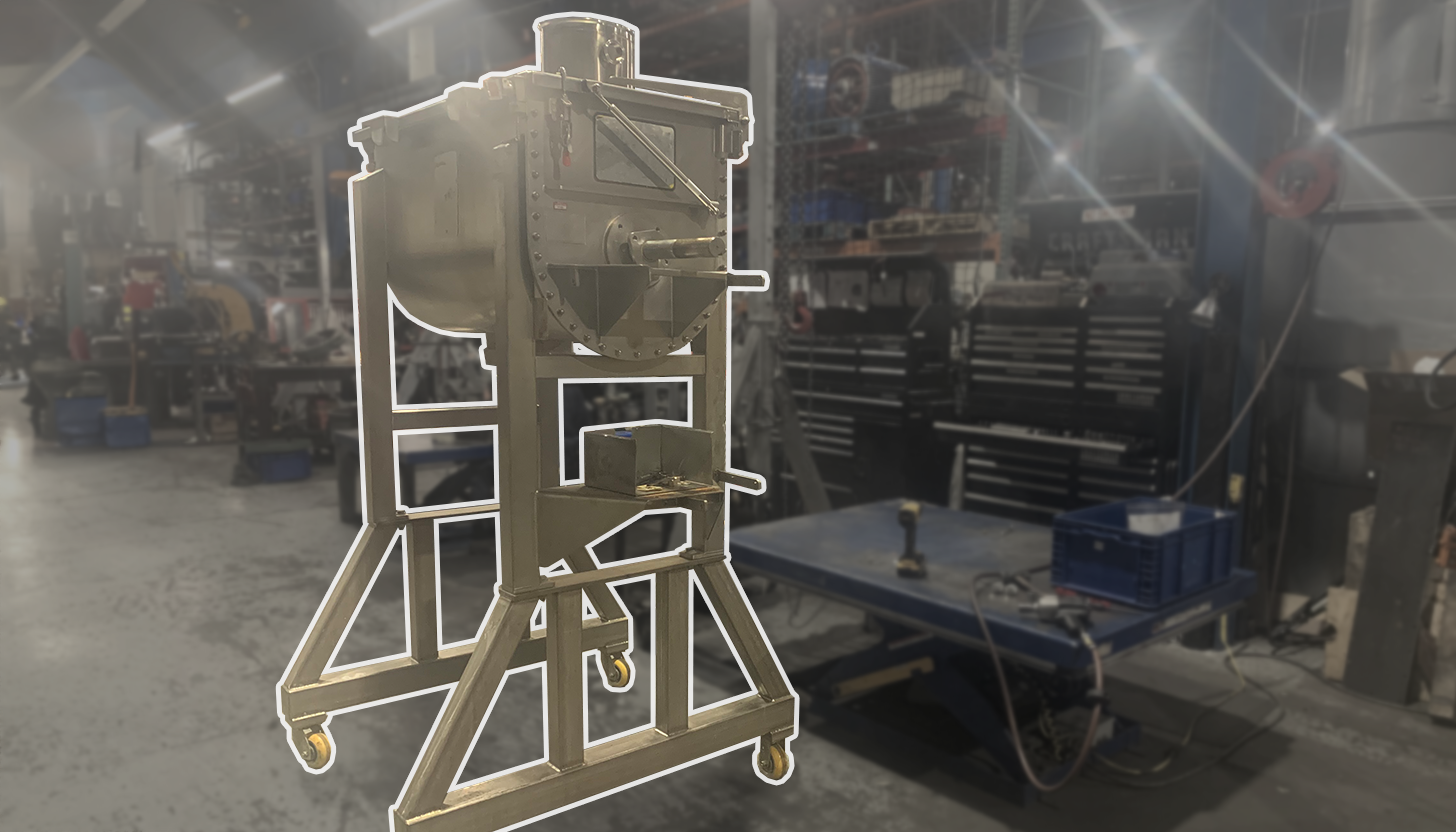

Explosion Proof Control Panel

The final touch to this comprehensive repair was replacing the legacy control panel with a brand-new, custom-designed, explosion-proof control panel. This upgrade modernized the machine’s operation and significantly enhanced safety, a concern in food manufacturing.

Outcome and Customer Benefit

Apex Industrial Automation’s specialized repair and upgrade resulted in a revitalized industrial blender that exceeded the customer’s expectations. Installing a new motor and gearbox breathed new life into the machine, providing the power and precision required for high-quality food production. The custom baseplate and laser alignment ensured smooth and efficient operation while introducing an explosion-proof control panel significantly enhanced safety and compliance.

Certifications and Standards

Quality Repairs for Many Types of Equipment

At Apex Industrial Automation, we take pride in our unwavering commitment to quality and safety. Our certifications and adherence to industry standards are testaments to this dedication. Our commitment to quality allows us to deliver unparalleled excellence in every aspect of our work, giving our customers confidence that they are partnering with a leader in the field.

Electrical Apparatus Service Association (EASA)

As one of only four Electrical Apparatus Service Association (EASA) shops in Northern Illinois, Apex adheres to the highest standards in custom specialty repair and general industrial electrical equipment. Our affiliation with EASA, a leading authority in the field, ensures that our repairs are conducted according to rigorous industry benchmarks and recommended practices. Being part of EASA’s network allows us to stay updated with the latest techniques and standards, such as ANSI/EASA AR100-2020. This affiliation highlights our expertise in industrial machinery repair.

UL-Certified Repairs

Apex’s UL certification for repairs, and dedication to meeting UL, 508A, UL-674A, and NNNY standards demonstrate our advanced capabilities in the repair and certification of custom specialty equipment and general industrial electrical equipment. These rigorous standards ensure the safety and reliability of your unique equipment, reinforcing our commitment to delivering high-quality repairs that meet the industry’s highest standards for performance.

Class 1, Division 1 – Groups C & D: We handle equipment in environments where flammable gases or vapors may be present.

Class II, Division 1 – Groups E, F & G: Our expertise extends to environments with combustible dust, where maintaining safety standards is crucial.